OLD AND RECENT MINING IN THE MONTAÑAS DO COUREL GEOPARK.

The mining resources of the natural contour of the Sierra de O Courel from Antiquity to the present day. Materials and exploitation systems: gold, iron, slate, lime and antimonite. What is its appearance in the natural environment? When, where and how were they exploited?

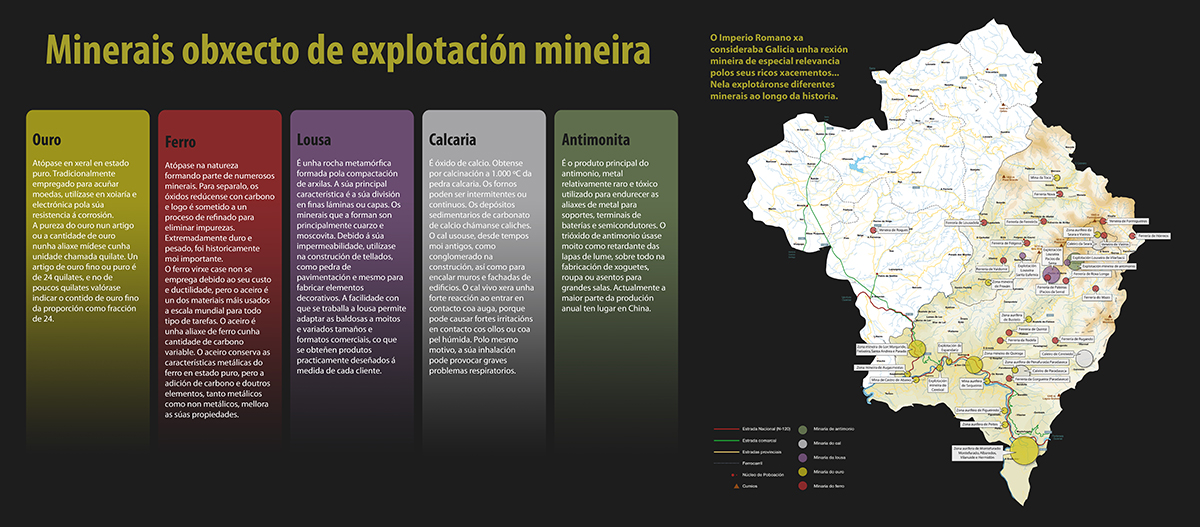

The Roman Empire already considered Galicia a mining region of special relevance due to its rich deposits… Different minerals were exploited here throughout history.

MINERALS OBJECT OF MINING EXPLOITATION

-GOLD

It is generally found in its pure state. Traditionally used to mint coins, it is used in jewelry and electronics for its resistance to corrosion. The purity of the gold in an item or the amount of gold in an alloy is measured by a unit called a karat. A fine or pure gold item is 24 carats, and in the few carats it is valued to indicate the fine gold content of the proportion as a fraction of 24.

-IRON

It is found in nature as part of numerous minerals. To separate it, the oxides are reduced with carbon and then it is subjected to a refining process to remove impurities. Extremely hard and heavy, it was historically very important. Virgin iron is rarely used due to its cost and ductility, but steel is one of the most used materials worldwide for all types of tasks. Steel is an iron alloy with a variable amount of carbon. Steel retains the metallic characteristics of pure iron, but the addition of carbon and other elements, both metallic and non-metallic, improves its properties.

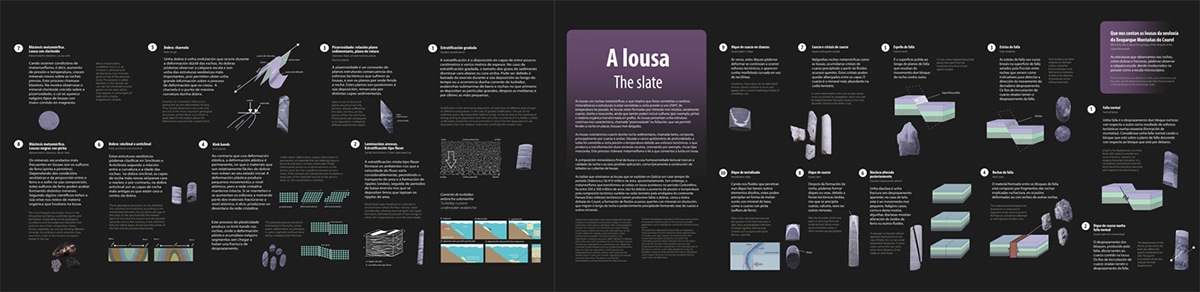

-SLATE

It is a metamorphic rock formed by the compaction of clays. Its main characteristic is its division into thin sheets or layers. The minerals that form it are mainly quartz and muscovite. Due to its impermeability, it is used in the construction of roofs, as a paving stone and even to make decorative elements. The ease with which slate is worked allows the tiles to be adapted to many and varied sizes and commercial formats, with which products are practically designed to suit each client.

-LIMESTONE

It’s calcium oxide. It is obtained by calcination at 1000ºC of limestone. Furnaces can be intermittent or continuous. Sedimentary deposits of calcium carbonate are called caliches. Lime was used, since ancient times, as a conglomerate in construction, as well as to whitewash walls and building facades. Quicklime generates a strong reaction when it comes into contact with water, because it can cause severe irritation in contact with eyes or wet skin. For the same reason, its inhalation can cause serious respiratory problems.

-ANTIMONITE

It is the main product of antimony, a relatively rare and toxic metal used to harden metal alloys for brackets, battery terminals, and semiconductors. Antimony trioxide is widely used as a flame retardant, particularly in the manufacture of toys, clothing, or large room seating. Currently most of the annual production takes place in China.

On the map: The Roman Empire already considered Galicia a mining region of special relevance due to its rich deposits…

Different minerals were exploited in it throughout history.

Map legend | |

National Highway (N-120) | Antimonite mining |

Local road | Limestone mining |

Railway | Slate mining |

Villages | Golden mining |

Summits | Iron mining |

SLATE MINING

This region, and in general the southeast of Galicia, is one of the largest slate exploitation centers in Spain. The extraction industry begins with the selection of the deposits and the planning of the work. This must take into account very diverse criteria, from the characteristics of the land to the reduction of the environmental impact of the action.

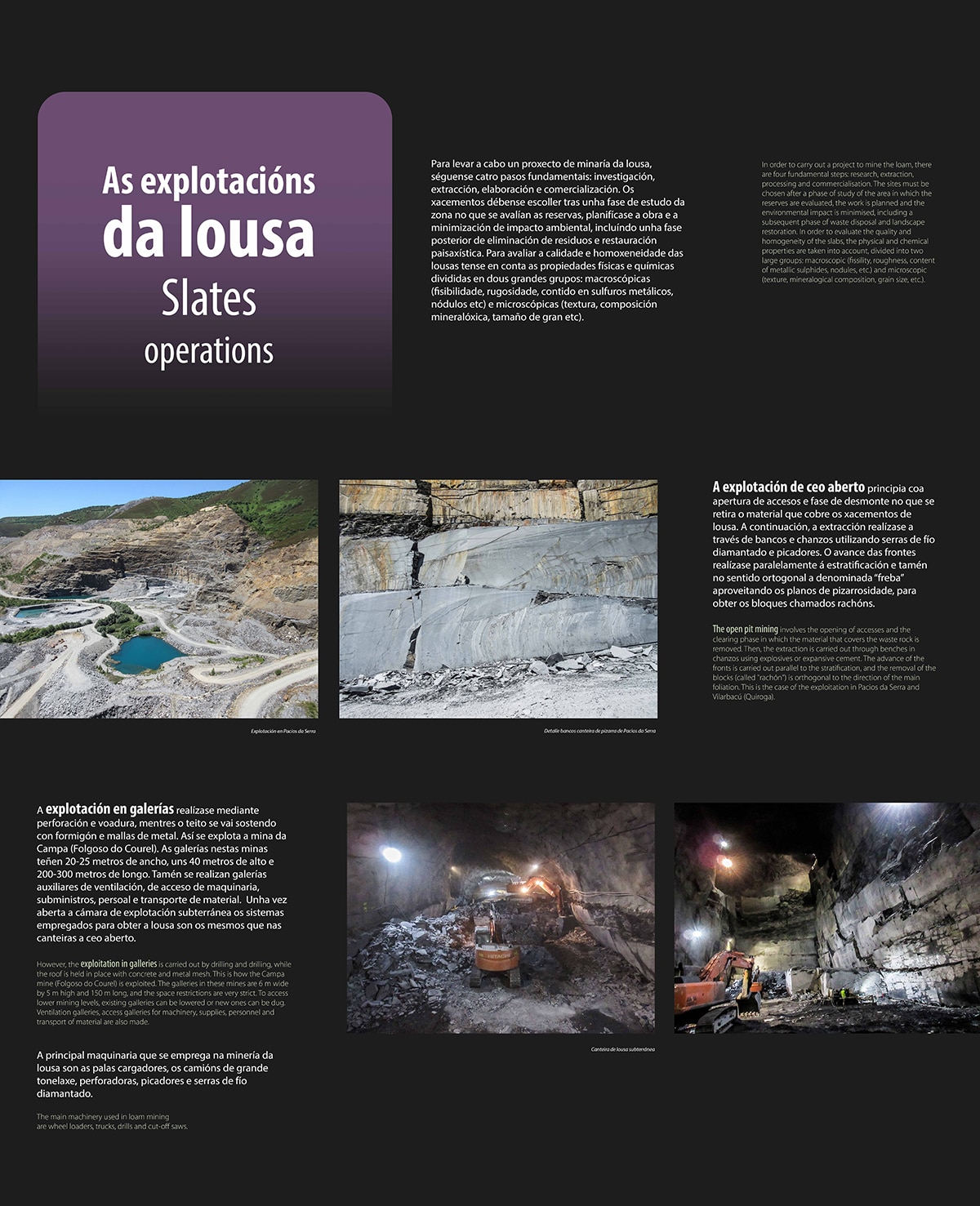

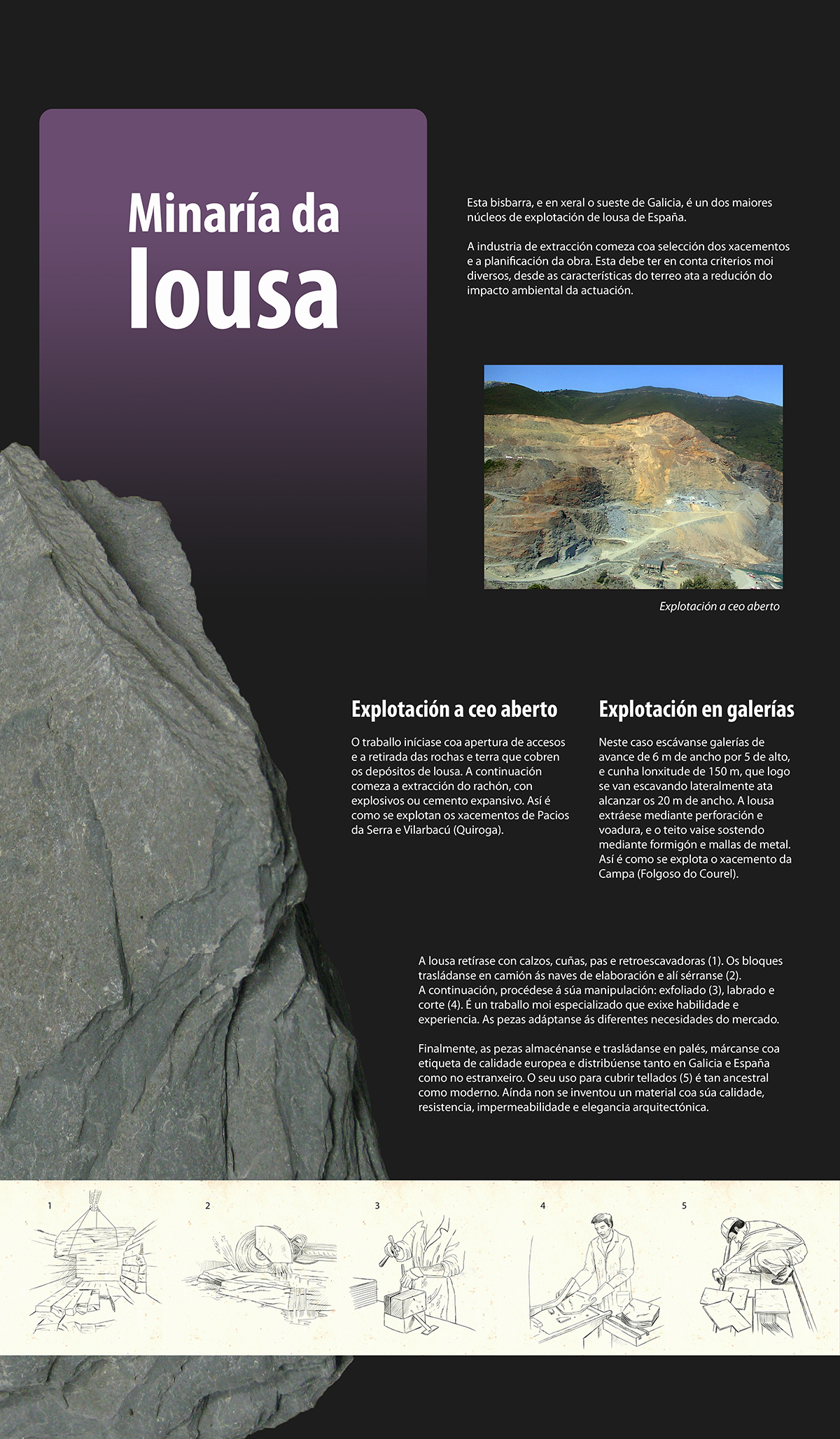

-OPEN SKY EXPLOITATION

The work begins with the opening of accesses and the removal of the rocks and earth that cover the slate deposits. Next, the extraction of the “rachón” begins, with explosives or expansive cement. This is how the deposits of Pacios de la Sierra and Vilarbacú (Quiroga) are exploited.

-EXPLOITATION IN GALLERIES

In this case, advance galleries are excavated 6m wide by 5m high, and 150m long, which are later excavated laterally until they are 20m wide. The tile is extracted by drilling and blasting, and the roof is supported by concrete and metal mesh. This is how the Campa deposit (Folgoso do Courel) is exploited.

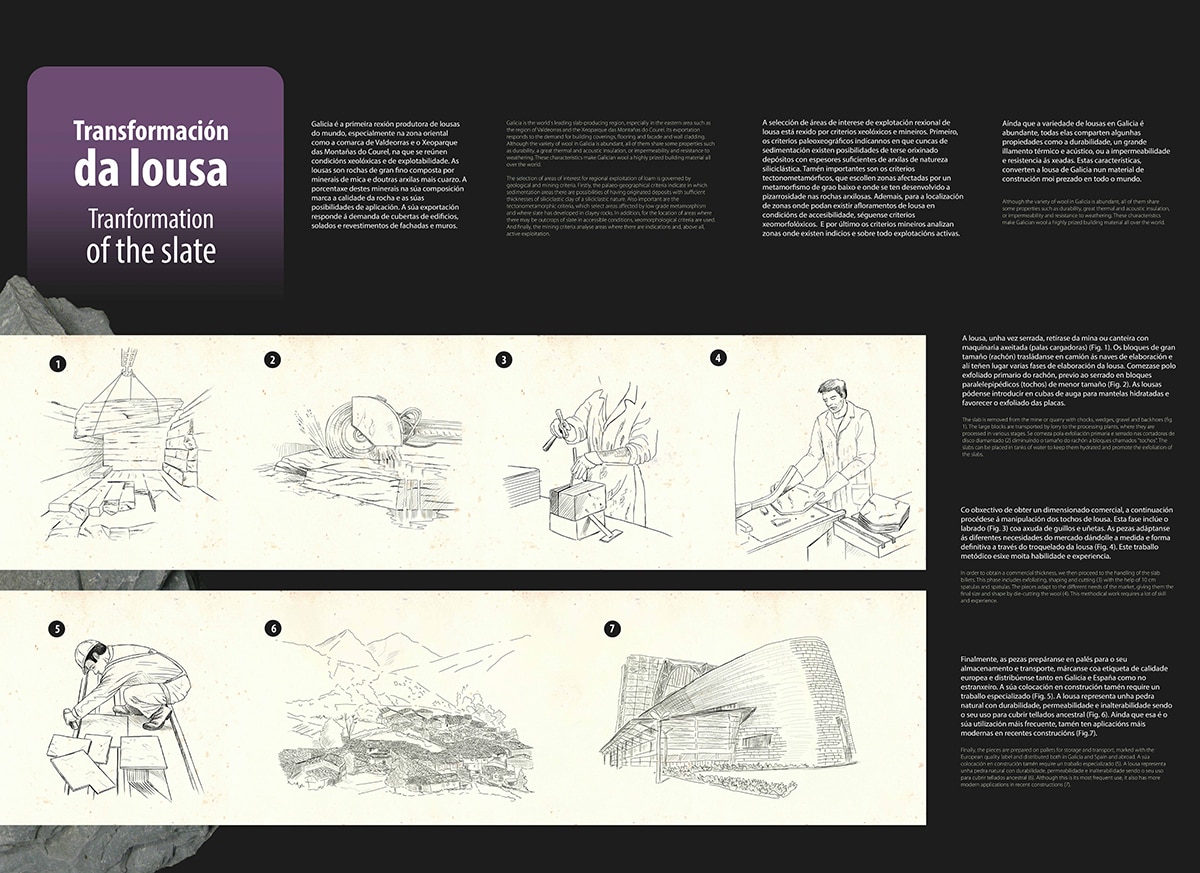

The slate is removed with wedges, wedges, shovels and backhoes. The blocks are transported by truck to the processing halls and there they are sawn. Next, we proceed to its manipulation: exfoliated, carved and cut. It is a very specialized job that demands skills and experience. The pieces are adapted to the different needs of the buyer.

Finally, the pieces are stored and moved on pallets, they are marked with the European quality label and distributed both in Galicia and Spain and abroad. Its use to cover roofs is as ancient as it is modern. A material with its quality, resistance, impermeability and architectural elegance has not yet been invented.

ROMAN GOLD MINING

The gold wealth of this area of Galicia was well known since antiquity. There are many traces that Roman gold mining left on our land two millennia ago. Based on their typology, exploitations can be divided into two large groups: exploitations on primary deposits and exploitations on secondary deposits.

-EXPLOITATION ON PRIMARY DEPOSITS: carried out to obtain gold-bearing minerals embedded in the rock. The extraction systems carried out in these deposits can be: trenches, open felling in the open air and underground mining through wells and galleries. The mines of A Toca in O Courel, Paradas in Vilarmel, Forgas and A Veneira in A Seara and Vieros are examples of this modality.

-EXPLOITATIONS ON SECONDARY DEPOSITS: are those carried out on fluvial alluvium or sediments that contain gold from primary deposits. In these deposits, the shavings are made using, among others, the following exploitation systems: pan washing of fluvial alluvium (as was done in Montefurado until recent times), diversion of the river bed (the Montefurado tunnel is the most significant in the Iberian Peninsula), erosion shell system (method used in the Sequeiros and Santa Andrea mines) and mining felling also called arrugia or ruina montium.

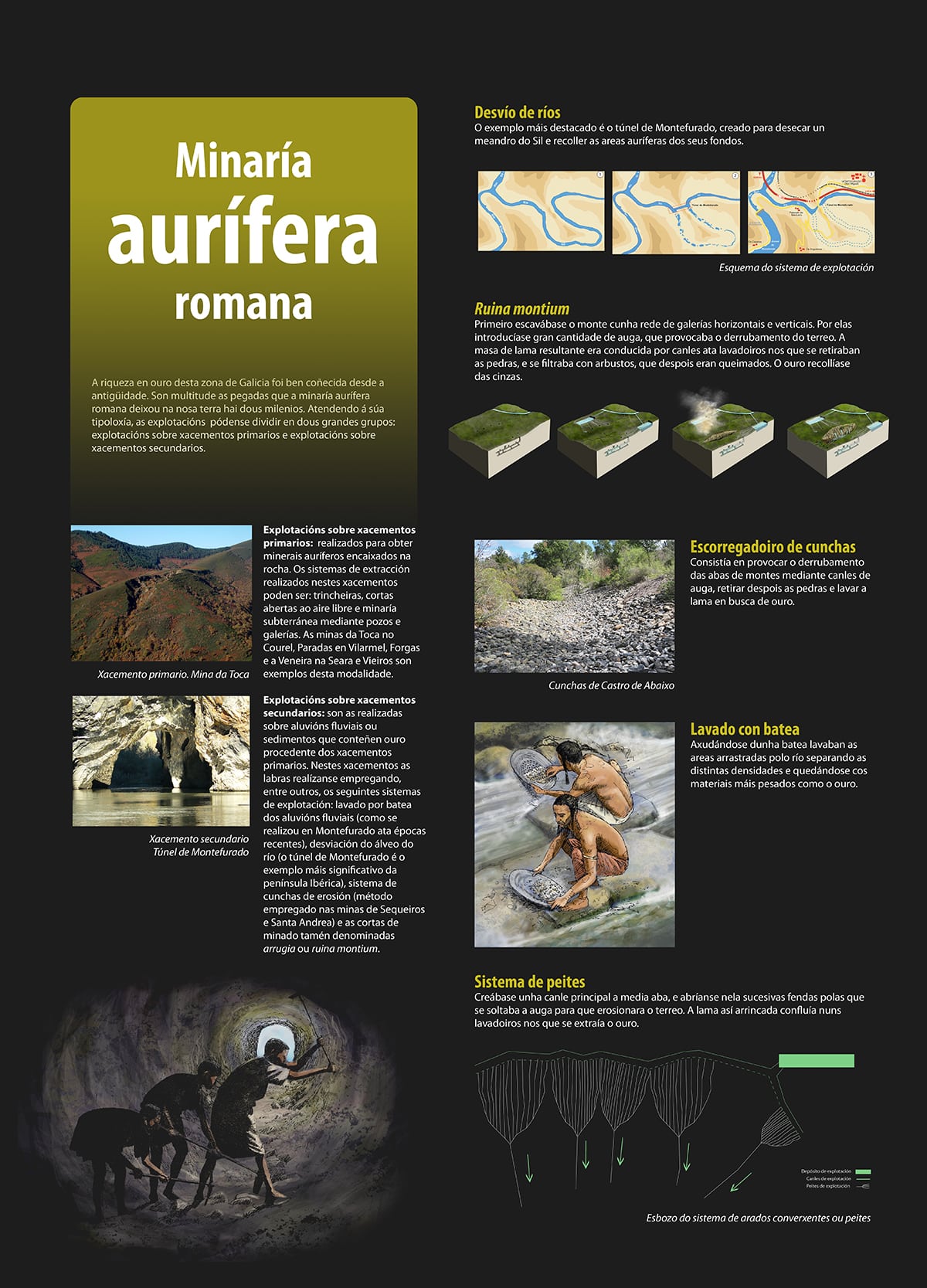

*RIVER DETOUR

The most outstanding example is the Montefurado tunnel, created to drain a meander of the Sil and collect the gold-bearing sands from its bottom.

*RUINA MONTIUM

First the mount was excavated with a network of horizontal and vertical galleries. A large amount of water entered through them, which caused the land to collapse. The resulting mass of mud was led through channels to sinks where the stones were removed, and it was filtered along with bushes, which were later burned. Gold was collected from the ashes.

*RUNOFF SHELL SYSTEM

It consisted of causing the collapse of the wings of mountains through water channels, then removing the stones and washing the mud in search of gold.

*GOLDPANNING IN THE RIVER

With the help of a punt, they washed the sand carried by the river, separating the different densities and keeping the heavier materials such as gold.

*”COMB” SYSTEM

A main channel was created in the wing of the mountain and successive fissures were opened in it through which the water was released to erode the terrain. The mud removed in this way flowed into some laundries where gold was extracted.

IRON MINING

The search for veins of gold by the Romans led to the detection of important deposits of iron, called “veneiras” in the Sierra de O Courel. Some of them were already worked by the pre-Roman settlers, such as Formigueiros, which is the most important in the entire area. The exploitation of iron was in the following centuries one of the main economic engines of these lands.

The iron industry was an important base of the local economy during much of the Middle Ages, with around 50 smithies in the O Courel area. The mines could be open pit or consist of small galleries. The extracted iron was lowered in carts or on the backs of donkeys and mules. In some areas, the unit of weight for the extracted mineral was the “quintal macho”, equivalent to the load that a donkey could carry, which was approximately 90 kilos.

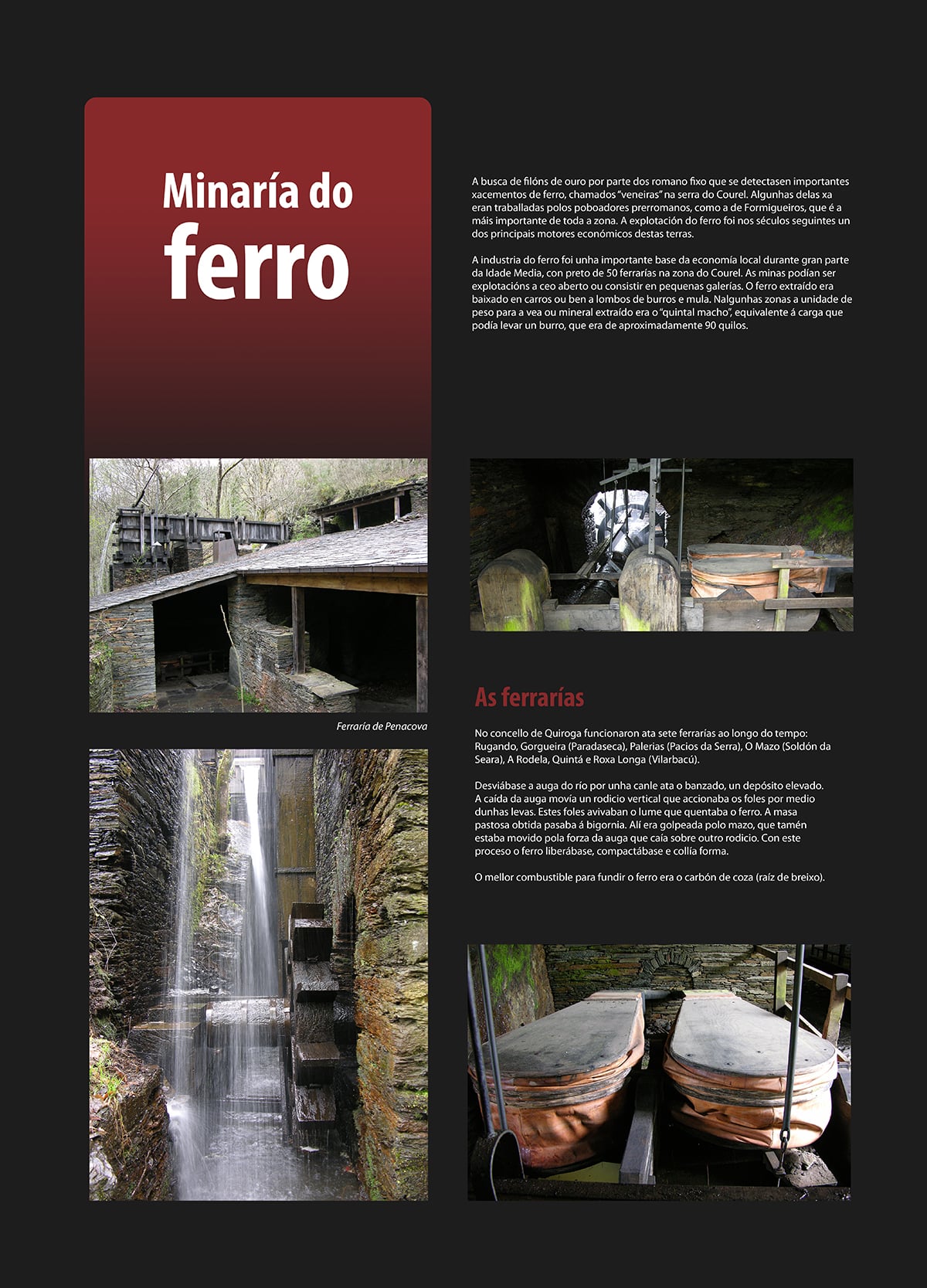

THE IRONWORKS

In the municipality of Quiroga up to seven smithies operated over time: Rugando, Gorgueira (Paradiseca), Paleiras (Pacios da Serra), O Mazo (Soldón da Seara), A Rodela, Quintá and Roxa Larga (Vilarbacú).

The river water was diverted through a channel to the “banzado”, a raised reservoir. The fall of the water moved a vertical wheel that activated the bellows by means of some cams. These bellows fanned the fire that heated the iron. The pasty mass obtained passed to the bigornia. There she was struck by the mallet, which was also moved by the force of the water falling on another wheel. With this process the iron was released, compacted and took shape.

The best fuel for smelting iron was briar charcoal.

LIMESTONE MINING

In those corners where there are small veins of this material or in its surroundings, a small activity related to the production of lime was maintained in the past. From then remains of what are known as lime kilns, lime kilns or lime kilns, are preserved in A Seara, Paradaseca and Cereixido.

These kilns were used to obtain lime from limestone, subjecting it to high temperatures with an open flame. This traditional process gave rise to the word “calcinar”. The lime obtained was always widely used to make mortar or cement, paint or whiten walls, in agriculture as a soil acidity corrector, to whiten clothes, to make paper and glass, or even for tanning. This enormous and varied work was carried out by lime makers.

The ovens are a construction of stone walls, open at the top, with a single opening or hole at the base of the wall to introduce the fuel. It used to be done on sloping land to take advantage of the excavated hole and save the construction of part of the wall.

THE LIME MANUFACTURING PROCESS WAS AS FOLLOWS:

-The limemaker was placing the limestone as an interior wall, leaving a wide central hole to set fire.

-The upper part is closed with stones forming a vault.

-Finally, the upper opening was covered with large slate flakes.

-The fire burned for about 60 hours and was maintained with heather and gorse: a single day consumed up to 50 carts of gorse. Such work required several people, who alternated every 4 hours, day and night.

-Once calcination was completed, the kiln was cooled for 3 days. The stones were removed from the upper part, already totally white, and they were marketed like this whole or ground

nd turned into powder.

ANTIMONITE MINING

Antimony is a soft, brittle, dense, lead-gray and silvery semi-metallic element. It occurs in compact masses, and is formed in low-temperature hydrothermal deposits or veins, usually in the form of sulphides. Its main mineral is antimonite.

In ancient times it was used in medicine and as a cosmetic to blacken the eyes. Currently we can find it in batteries, accumulators, cable coating, bearings or bearings. It is of increasing importance in the semiconductor industry and in the production of diodes or infrared detectors. Antimony trioxide is used as a flame retardant for clothing, toys, or seat covers.

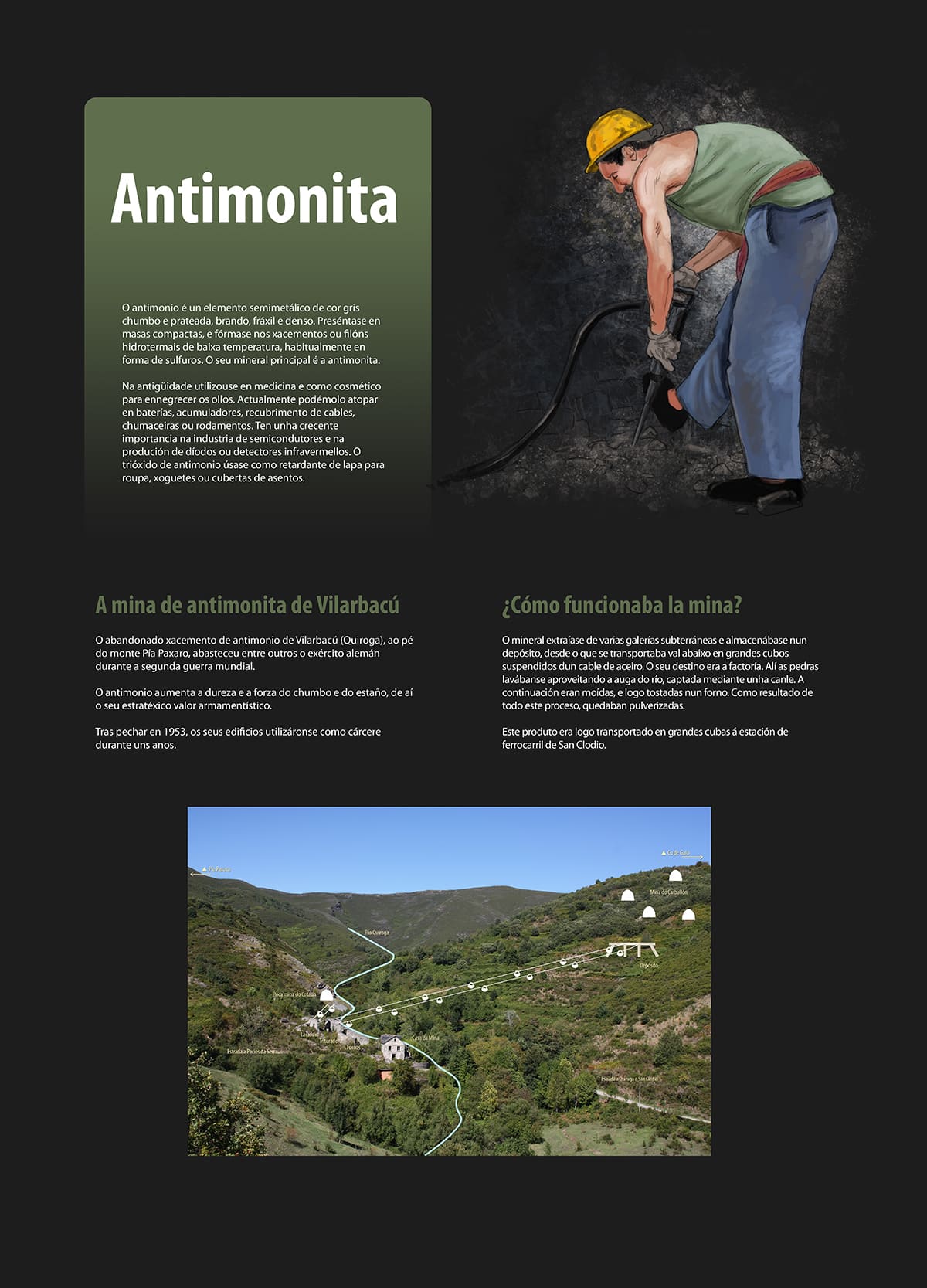

VILARBACÚ ANTIMONITE MINE

The abandoned antimony deposit of Vilarbacú (Quiroga), at the foot of Mount Pía Paxaro, supplied, among other things, the German army during the Second World War.

Antimony increases the hardness and strength of lead and tin, hence its strategic weapon value.

After closing in 1953, its buildings were used as a prison for a few years.

HOW MINE WORKED?

The ore was extracted from several underground galleries and stored in a warehouse, from which it was transported down the valley in large buckets suspended from a steel cable. His destination was the factory. There, the stones were washed using the river water, collected through a channel. They were then ground, and then roasted in an oven. As a result of all this process, they were pulverized.

This product was then transported in large vats to the San Clodio railway station..